Fast robotic solutions

Acieta offers an extensive line of standard products to help you overcome your shop floor challenges. Whether you’re looking to increase productivity or free up shop space or fill your labor shortage gap, an Acieta standard product can help!

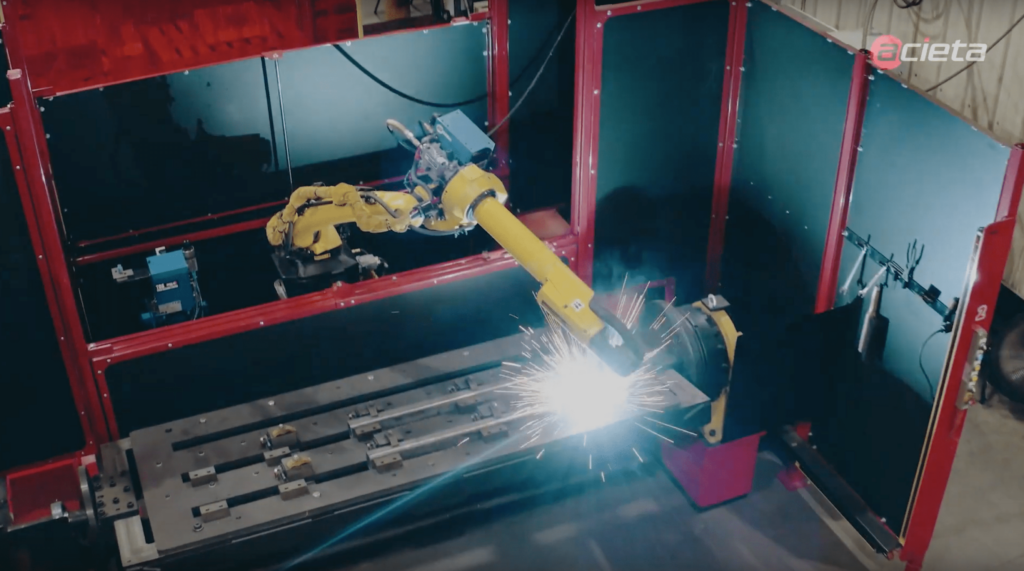

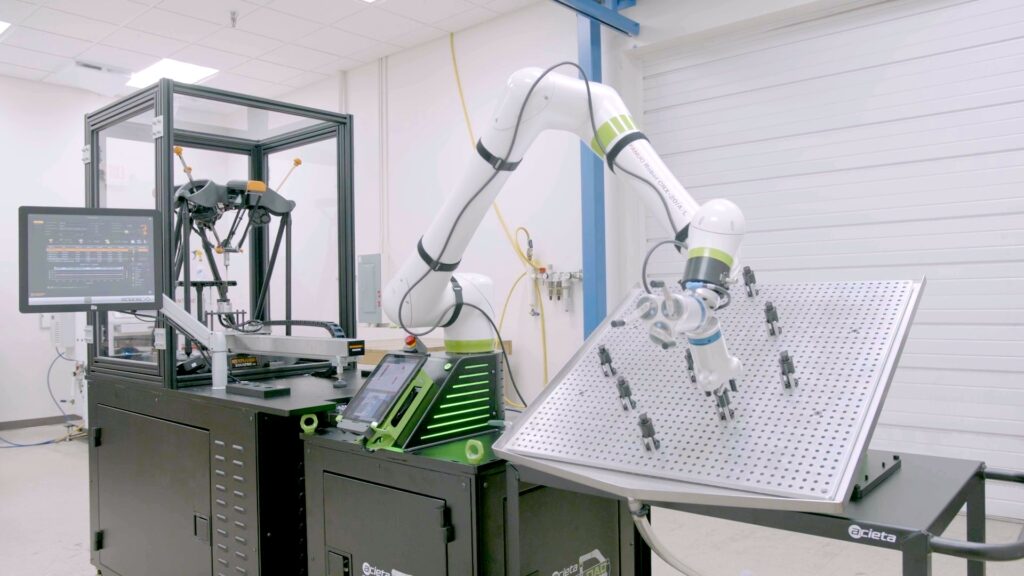

From our FastLOAD machine tending series and FastARC weld cells to our FastBEND press brake tending series and FastPACK palletizing system, Acieta has a standard solution to keep you competitive.

Why FAST, you ask…it is Acieta’s commitment to you that we offer standard products with FAST delivery, FAST set-up, FAST learning and most of all, FAST ROI. Most standard products will see a payback in 12 months!