The FastLOAD CX1000 can operate up to two different machines simultaneously for optimal throughput. Most shops see an ROI in 6 to 12 months*. (*Average ROI utilizing 2 shifts)

Videos

FastBEND Gives Manufacturers Instant Advantage

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Read More

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Operating press brakes is a potentially dangerous part of sheet metal forming and metal part fabrication. But what if you could produce more, higher-quality parts without adding risk to your workers? The FastBEND® robotic cell can be integrated with new or existing press brakes to process a wide variety of formed parts.

Legends Are Forever: Robotics Pioneer Retires After Growing The Industry For Four Decades

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

Read More

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

An industry legend. A pioneer. A visionary. All those words describe John Burg, who has been integral in expanding the use of robotics in the manufacturing industry for the last four decades. John’s retirement in February 2022 marks the end of an era. He began his legacy in the 1980s, a time when no one but the big automotive OEMs were using robots to improve operations. John saw the future of robotics as a technology adoptable by small and medium manufacturers as well, and he began a long journey to help grow robotics become what it is today: affordable, smarter, faster and accessible to all.

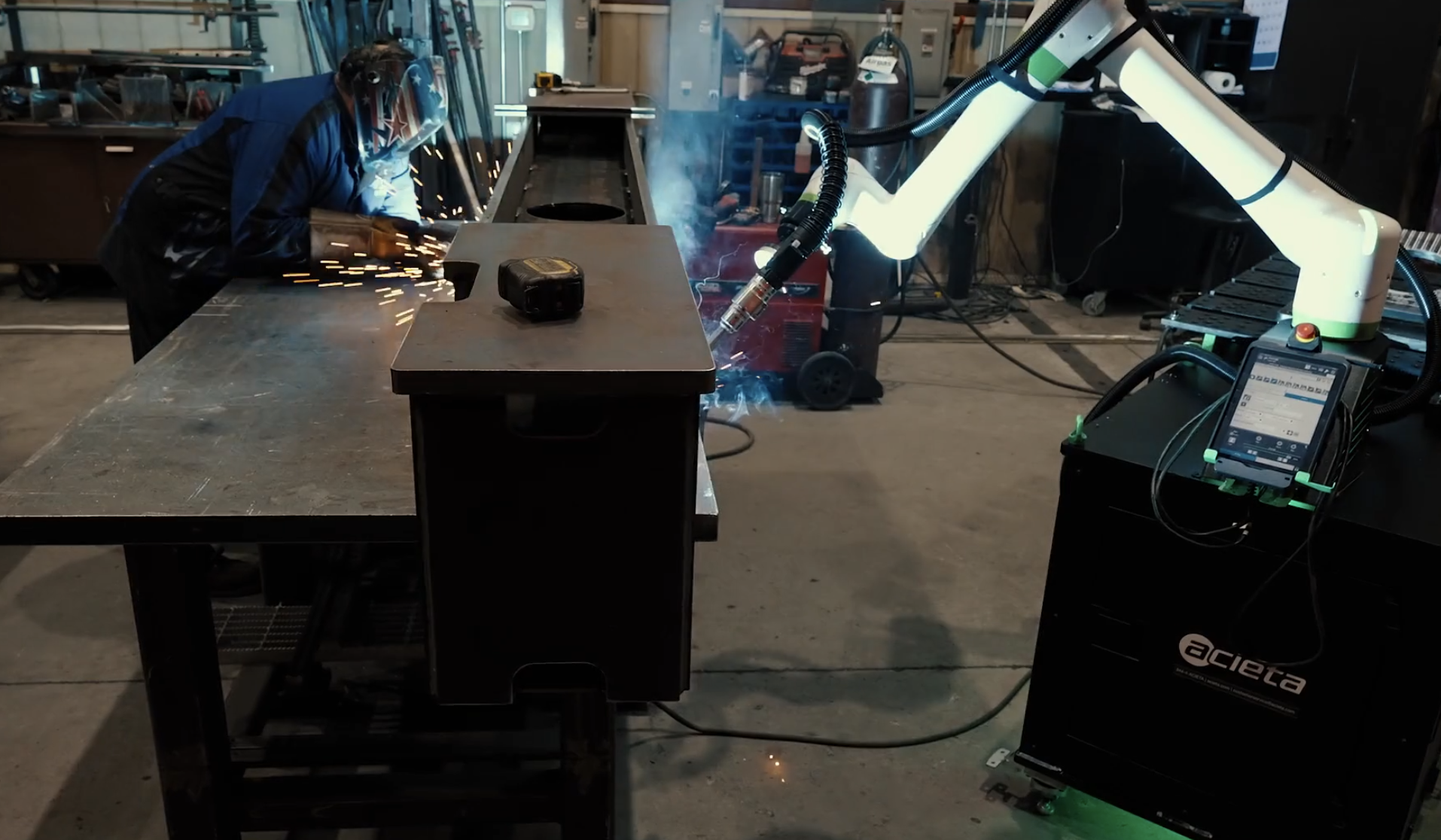

Fabricator Achieves Optimal Quality and Productivity With A Welding Robot

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Read More

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Fab shop MDS Manufacturing originally thought they were too small to afford a robot, but then they installed a FastARC 2HT standard robotic welding solution. Now they save a lot of time on processing, keep the lines running without roadblocks, eliminate the need for most rework, and have relieved fatigue from repetitive work for the manual welding operators.

Robotic Welding Increases Productivity at MDS

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

Read More

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

Robotic welding helps increase productivity and reduce workers' repetitive welding tasks. The FastARC 2HT standard robotic welding solution from Acieta provides high-quality, accurate and repeatable welds all day, every day. See how MDS Manufacturing uses the FastARC 2HT robotic welding solution to do the repetitive welding and keep workers happy.

How To Set Up An Acieta Fastarc Robotic Welding System (ST, TT, DT models)

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

This quick start guide gives you 7 simple steps to set up a your new Acieta FastARC robotic welding system (ST, TT, DT models). Get tips on how to go from unboxing to system start-up...fast.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Simple Drag And Drop Robot Programming Has Never Been Easier!

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Check out this very simple drag and drop robot programming available on the FastLOAD CX1000 standard collaborative expandable cell! Get a virtual or in-person demo today - info@acieta.com | 844-4-ACIETA. /cx1000/

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Mobile Collaborative Robot Provides Freedom & Flexibility On The Shop Floor

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Read More

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Jake Corning demonstrates how to use the easiest, most flexible cobot ever--the FastLOAD CX1000. Watch as workers wheel the cart-mounted robot into place, set it up in seconds, quickly replace snap-on grippers, and program the system with an intuitive touch screen interface. It’s the collaborative robot everyone can use.

Get Production Back Up To Speed

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

Read More

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

Now is a challenging time for companies to recover fast and get production back up to speed to stay competitive in the market. For machine shops facing capacity challenges, labor shortages and quality variability, Acieta introduces the new FastLOAD® DR2000 robotic cell, which can be ready for delivery in 8 weeks. Address core business challenges, fast. Low commitment, fast entry to automation. Fast lead time.

Intuitive Drilling with Acieta

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

Read More

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

What was at first a dangerous operation, Acieta’s robotic solution amplified this drilling process. This customer is able to fully customize and adjust their FANUC robot capabilities on nearly any desired drillable material. Additionally, this new process streamlines what used to require numerous man hours for repositioning and loading materials alone. Our premier robotic integration solutions allow your business to mitigate the grunt work, freeing workers for more creative endeavors and sparing them the strain on their bodies. Acieta’s solutions alleviate scrap waste and manual labor while boosting the consistency of your products. With guaranteed accuracy, capability, and repeatability, the result brings significant ROI. If you are currently using a crane to lift and rotate materials due to sheer weight, stop putting your team at risk and contact us today.

Robots Bend, Weld and Palletize for Metal Fabricator

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

Read More

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

Cotterman, a manufacturer of rolling metal ladders, wanted to reduce freight costs by centralizing the manufacturing of ladder parts to one plant. To help, Acieta designed a multi-application robotic system with three FANUC arms that run 24/7, seamlessly making ladder treads from bending to welding to palletizing. As a result, Cotterman has saved on floor space, reduced shipping costs, improved turnaround time and streamlined labor, delivering a XX ROI for the company. See this innovative robotic system in action.

Company Moves To State-Of-The-Art Automation To Improve Efficiency And Worker Training

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

Read More

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

Acieta installed a RIBS (Robotically Integrated Bending Solutions) system at the Chassis Division of Lippert Components, Inc., in Goshen, Indiana. The new automated press brake system improves efficiency, reduces costs and facilitates team member training. Video courtesy of Lippert Components.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: