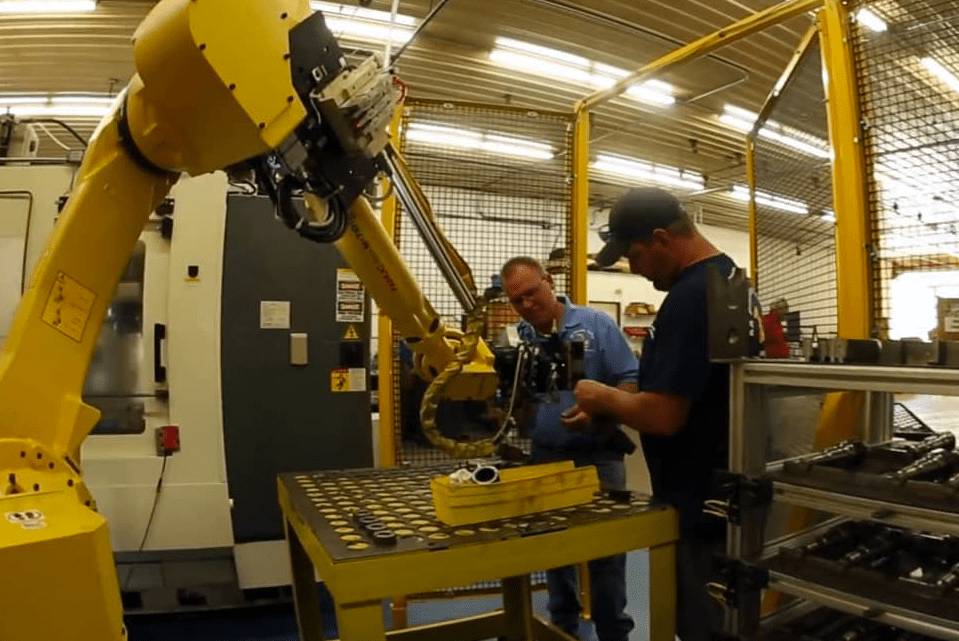

Automation has been part of the industrial landscape for decades and continues to expand as new technology is developed. Designed to fulfill some of the most repetitive and/or dangerous tasks, automation can provide numerous advantages to organizations, employees and the economy, which accounts for its continued growth throughout the manufacturing sector.

A few benefits of automation include:

- Increased productivity: Since its inception, automation has increased the speed, accuracy and repeatability of industrial operations. It allows work to be completed at higher capacity without compromising quality, giving facilities a competitive edge.

- Improved safety for human workers: Automation can help reduce the number of employee injuries by accomplishing high-risk, repetitive, and dangerous tasks.

- Innovation and core specialties: With automation, workers can focus on more engaging and specialized roles that set a facility apart.

In addition to these advantages, there are multiple economic benefits of automation.

The Effects of Automation on the Economy

When it comes to automation, you may hear concerns that robots take jobs away from human workers. Robots do the dangerous work resulting in improved overall efficiency so people can focus on more engaging and important tasks. Automation has been proven to create more jobs in manufacturing — up to 750,000 by some estimates and that number will continue to grow.

The impact of industrial robots on the economy as a whole is very positive. The benefits include:

- More competitive For many manufacturers, there is no way to remain competitive in business without automation. Because these systems can run with high speed precision, manufacturers utilize robotic automation to gain a competitive edge.

- New and different jobs: Automation continues to change the face of industry, including the types of jobs continually created. For example, automated machinery must be programmed, managed and maintained properly. While these responsibilities differ from the historical manufacturing duties, they are now among the most common and important roles in the field.

- Protection against unexpected scenarios: The coronavirus spread quickly, and much of the world was underprepared. For many facilities, robots could serve as a buffer against shutdowns and capacity limitations, enabling operations to continue at some scale with minimal headcount. As we navigate an uncertain future, automation is one sure way to provide peace of mind.

Robotic Solutions from Acieta

At Acieta, we offer extensive expertise in developing and providing automated solutions for many applications, at any scale. Whether you want to incrementally expand your existing equipment or overhaul an entire system, we are ready to help and look forward to working with you.