Blog

Preparing Your Manufacturing Business for Mexico’s Evolving Market

I’ve seen firsthand how manufacturing in Mexico is changing. Mexico’s strategic location within North America, its skilled workforce, and solid infrastructure make it an attractive nearshore partner. But what really makes a difference now is how automation is helping manufacturers in Mexico operate more efficiently and stay competitive. Why Mexico Is Still a Top Choice ... Preparing Your Manufacturing Business for Mexico’s Evolving Market

The Secret to Smarter Manufacturing: Building a Solid Automation Roadmap

Today’s manufacturing landscape demands more than just producing good products and relying on skilled workers. To stay competitive, you need a clear strategic plan, a solid automation roadmap that guides your vision toward more efficient and smarter operations. Think of it as a detailed blueprint for transforming manual tasks into automated processes, elevating quality, reducing ... The Secret to Smarter Manufacturing: Building a Solid Automation Roadmap

The Power of Mentorship and Internships: Building Strong Communities in Manufacturing and Robotics

Acieta Internship Video Think about a time someone believed in you—when they took the time to share what they knew, listen to your questions, and encourage you to aim higher. That kind of support can really make a difference in someone’s life. It boosts confidence, sparks passion, and creates effects that last well beyond that ... The Power of Mentorship and Internships: Building Strong Communities in Manufacturing and Robotics

Building a Future-Proof Factory: From Fragmented Systems to Enterprise-Level OEE Ahead of Automate 2025

As we look toward Automate 2025 in Detroit, the conversation is shifting. Manufacturers aren’t just trying to automate—they’re trying to scale, unify, and optimize end-to-end operations. And after 25 years in industrial automation, I can tell you: the most powerful lever we have is OEE—but not just on the shop floor. OEE—Overall Equipment Effectiveness—has evolved. ... Building a Future-Proof Factory: From Fragmented Systems to Enterprise-Level OEE Ahead of Automate 2025

Harnessing Real-Time Feedback: The Key to Thriving in Manufacturing

In the rapidly evolving manufacturing landscape, comfort can transform into a risk. While the status quo may feel safe, reliance on outdated processes can lead to being left behind in an industry increasingly defined by automation and data utilization. The Risks of Tradition in Quality Assurance Too often, manufacturers depend on conventional quality checks that ... Harnessing Real-Time Feedback: The Key to Thriving in Manufacturing

The Future of Trailer Manufacturing: A Vision for Innovation

Standing on the production floor, the scene is all too familiar—workers drilling 100s of holes into each trailer, meticulously driving screws into place. It’s a process that trailer manufacturers know well, characterized by labor-intensive methods that strain productivity and workforce morale. This story is rooted in a distinguished manufacturer with a rich history of evolution ... The Future of Trailer Manufacturing: A Vision for Innovation

Cocoa, Cookies, and Robotics

The holiday season is just around the corner, and food and beverage manufacturers are already gearing up to make sure all little boys and girls have plenty of cookies and milk for you know who! And if you’re a manufacturer who hasn’t found a way to automate critical aspects of your operation, the coal those ... Cocoa, Cookies, and Robotics

Navigating the Future of North American Manufacturing: Impacts of Political Shifts on Tariffs, Labor, and Automation

As the dust settles from the recent U.S. presidential election and a Republican administration prepares to take office, manufacturing leaders and investors across North America are evaluating potential changes in policy and their strategic implications. For those of us involved in robotic system integration and manufacturing automation, these shifts hold particular significance. Here’s an analysis ... Navigating the Future of North American Manufacturing: Impacts of Political Shifts on Tariffs, Labor, and Automation

The Challenges Facing Modern Manufacturing: Labor Shortages, Safety, and Global Competition

In today’s fast-paced global economy, manufacturers face a unique set of challenges that require both innovation and adaptability to overcome. While automation and technological advancements offer significant improvements, many companies continue to grapple with the realities of labor shortages, maintaining safety standards, and staying competitive in a world where lower-wage countries dominate certain markets. Nowhere ... The Challenges Facing Modern Manufacturing: Labor Shortages, Safety, and Global Competition

Transforming Manufacturing Efficiency: A Success Story from Joplin, MO

In the fast-paced world of manufacturing, efficiency is key. With tight deadlines and increasing competitive pressures, manufacturers are continuously seeking innovative solutions to streamline operations, boost productivity, and optimize floor space—all while addressing ongoing labor shortages. This is where Acieta steps in, transforming machine shops with both its custom and standard robotic solutions like the ... Transforming Manufacturing Efficiency: A Success Story from Joplin, MO

Join Us at IMTS 2024: Where Innovation Meets Industry

IMTS SHOW SPECIALS In an era of rapid technological change, it’s crucial for manufacturers to adapt and evolve. At IMTS 2024, Acieta is excited to showcase how our combined expertise can transform your operations and position you for success. Join us at Booth #236419 to discover solutions that can help you tackle today’s challenges and ... Join Us at IMTS 2024: Where Innovation Meets Industry

Igniting Change: The Power of Community-Driven Education

In today’s fast-paced, technology-driven world, the importance of strong, thriving local communities cannot be overstated. While global initiatives often steal the spotlight, it’s the grassroots efforts that truly ignite sustainable change. These local efforts fuel innovation, education, and economic growth, laying the foundation for future leaders who will drive industry advancements. One such inspiring example ... Igniting Change: The Power of Community-Driven Education

What CPG Manufacturers Don’t Know About Packaging Automation

Picture this: You’re a CPG manufacturer facing the usual suspects—tight deadlines, labor shortages, and the constant pressure to keep up with market demands. You’ve heard about robotic packaging automation, and it sounds like a dream come true. But is it just about the fancy machines, or is there something more? Let’s cut to the chase. ... What CPG Manufacturers Don’t Know About Packaging Automation

Exciting News: Acieta Acquires Capital Industries to Enhance Automation Solutions

Acieta, a leader in industrial robotic automation solutions, is thrilled to announce the acquisition of Capital Industries, a distinguished player in material handling, assembly systems, feeding systems, test systems, and control systems. This strategic acquisition enhances our ability to deliver unmatched expertise and innovative solutions to manufacturers, reinforcing our commitment to providing ‘Your ... Exciting News: Acieta Acquires Capital Industries to Enhance Automation Solutions

How Regular Maintenance Can Prevent Breakdowns and Minimize Downtime

In the fast-paced world of manufacturing, every minute counts. When your production line is down, it’s not just frustrating—it’s costly. The key to keeping your operations running smoothly is regular maintenance. At Acieta, we understand the critical importance of maintaining your robotic automation systems to prevent unexpected breakdowns and minimize downtime. Let’s explore how regular ... How Regular Maintenance Can Prevent Breakdowns and Minimize Downtime

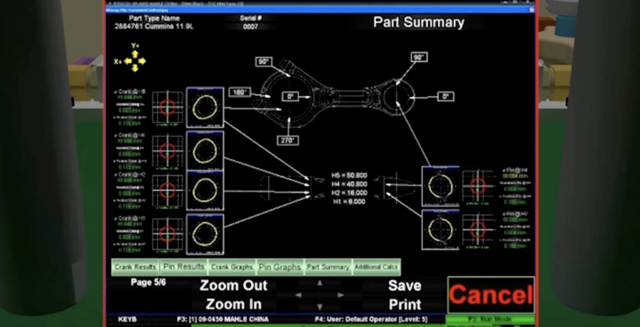

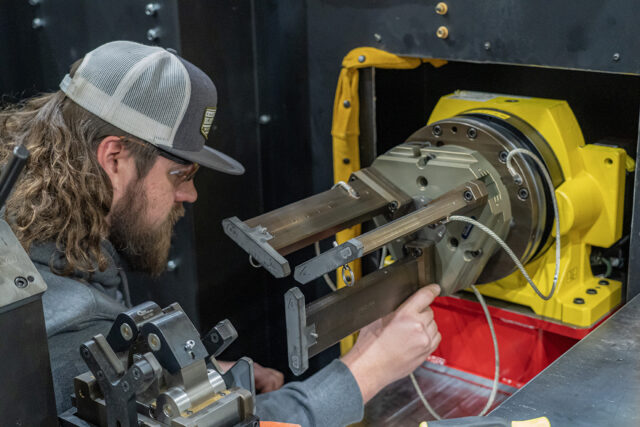

Advanced Inspection for Engine Manufacturing

In the fast-paced world of automotive and diesel engine manufacturing, precision and efficiency are non-negotiable. Acieta | +Vantage offers advanced inspection systems that set new standards in quality control, empowering manufacturers to produce superior components with confidence. Unmatched Precision and Efficiency Acieta | +Vantage’s cutting-edge technology utilizes high precision rotary air bearings for dynamic scanning, ... Advanced Inspection for Engine Manufacturing

Discover a Powerhouse of Expertise and Sharpen Your Automation Edge at Automate 2024

Join Acieta at Automate 2024, where innovation meets expertise in Booth #4002 from May 6-9 in Chicago, Illinois. As a leader in standard and custom robotic automation, Acieta is proud to announce a significant transformation as it brings RōBEX, +Vantage Corporation, and Mid-State Engineering under its banner. This strategic integration will debut at Automate 2024, ... Discover a Powerhouse of Expertise and Sharpen Your Automation Edge at Automate 2024

Women in Robotics Share Their Paths to Joining the Manufacturing Industry

Traditionally, manufacturing jobs have been predominantly filled by men, but today the number of women in manufacturing careers is on the rise. In recognition of Women’s History Month, we highlight some women in robotic automation who are today’s history makers, those laying a foundation for generations to come by contributing to the growth of an ... Women in Robotics Share Their Paths to Joining the Manufacturing Industry

Innovate, Integrate, Inspire: The Path to a Robotics-Enhanced Workforce

In the dynamic world of manufacturing, robotics stands at the forefront of innovation and efficiency, offering a compelling solution to the labor gap while enhancing the skills and satisfaction of the workforce. This positive synergy between humans and machines is reshaping the industry, creating opportunities for growth, innovation, and enhanced job satisfaction. Addressing the Labor ... Innovate, Integrate, Inspire: The Path to a Robotics-Enhanced Workforce

Troubleshooting Common Robot Problems

Modern industrial robots are robust; issues with joints, motors, encoders, and controllers are rare. However, robot cells are intricate assemblies with numerous components that will wear and eventually fail over time. Cables, even the high-flex versions, are an example of where faults can occur. Good robot troubleshooting skills are essential to get to root causes like ... Troubleshooting Common Robot Problems

Why Industrial Robot Maintenance Is Critical

One of the advantages of robots over other types of industrial automation is that they can be retrained. If the task for which they were purchased goes away they can be redeployed elsewhere, letting the business continue to recoup their investment. This is especially true when a robot’s working life is prolonged through regular preventive ... Why Industrial Robot Maintenance Is Critical

Empower Your Team with Acieta’s Training Programs

Your company’s success in the world of manufacturing hinges on more than just the acquisition of cutting-edge robotic systems; it depends on the expertise and confidence of the team that operates and maintains these systems. Here’s how training with Acieta can significantly benefit your company: Improved Efficiency and Productivity Our training classes, led ... Empower Your Team with Acieta’s Training Programs

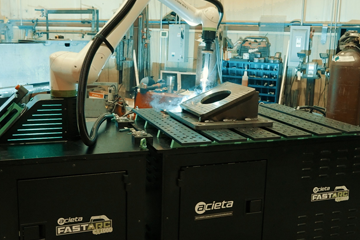

What Are Welding Cobots And Why Should You Use Them?

Industries that rely on experienced welders are about to experience a significant labor shortage. Many will need technological and automated solutions to maintain productivity and profitability. More than 400,000 people work in the U.S. welding trades, with a high employment concentration in manufacturing, according to the Bureau of Labor Statistics. The average age of an employee in ... What Are Welding Cobots And Why Should You Use Them?

What Is The Difference Between Robots And Cobots?

Ignore the stories about robots taking jobs — manufacturers are using robots to do the jobs they can’t find people for. Labor shortages are a growing problem for many businesses, which is one reason they are investing in automation in general, and robots in particular. Robots increase capacity, improve quality, make the workplace safer and ... What Is The Difference Between Robots And Cobots?