Manual rivet work slows your line, drives up costs, and puts your team at risk. A tailored solution that speeds up production, cuts labor, and improves safety can change everything. More trailers, fewer headaches designed to fit your operation. Let’s create a system built for you.

Videos

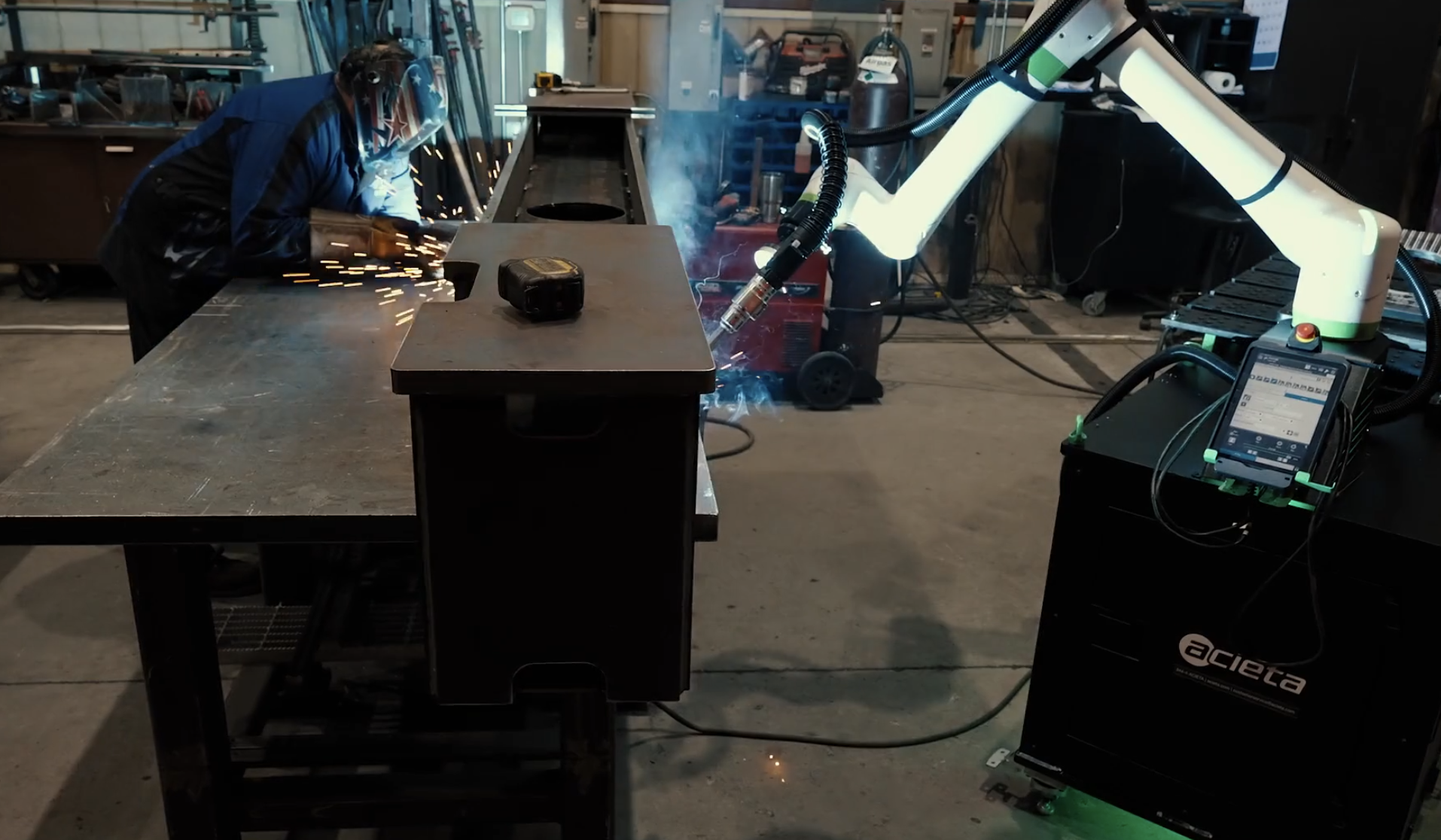

Empowering Your Team with Automation

Looking for ways to boost safety, efficiency, and employee well-being? This video shares real stories from Akim and Jeremy, two workers who’ve seen firsthand how robotics are transforming their workday. They talk about how automating repetitive tasks not only makes their jobs safer and less tiring, but also speeds up production—allowing them to get more done in less time. If you're wondering how technology can help your team work smarter instead of harder, this video shows practical results that could inspire your next move toward automation. Akim and Jeremy share how introducing robotics into their daily tasks has made their jobs safer, less physically demanding, and more efficient. By automating repetitive chores, they can focus on what truly matters—reducing injuries and completing more work in less time. Seeing is believing—discover how adding automation can make a real difference in your operation. Interested in making your workplace safer and more productive? Contact us today to learn how automation can help your team work smarter.

Read More

Looking for ways to boost safety, efficiency, and employee well-being? This video shares real stories from Akim and Jeremy, two workers who’ve seen firsthand how robotics are transforming their workday. They talk about how automating repetitive tasks not only makes their jobs safer and less tiring, but also speeds up production—allowing them to get more done in less time. If you're wondering how technology can help your team work smarter instead of harder, this video shows practical results that could inspire your next move toward automation. Akim and Jeremy share how introducing robotics into their daily tasks has made their jobs safer, less physically demanding, and more efficient. By automating repetitive chores, they can focus on what truly matters—reducing injuries and completing more work in less time. Seeing is believing—discover how adding automation can make a real difference in your operation. Interested in making your workplace safer and more productive? Contact us today to learn how automation can help your team work smarter.

Looking for ways to boost safety, efficiency, and employee well-being? This video shares real stories from Akim and Jeremy, two workers who’ve seen firsthand how robotics are transforming their workday. They talk about how automating repetitive tasks not only makes their jobs safer and less tiring, but also speeds up production—allowing them to get more done in less time. If you're wondering how technology can help your team work smarter instead of harder, this video shows practical results that could inspire your next move toward automation. Akim and Jeremy share how introducing robotics into their daily tasks has made their jobs safer, less physically demanding, and more efficient. By automating repetitive chores, they can focus on what truly matters—reducing injuries and completing more work in less time. Seeing is believing—discover how adding automation can make a real difference in your operation. Interested in making your workplace safer and more productive? Contact us today to learn how automation can help your team work smarter.

The Age of Automation is NOW

CNC Machine Products Inc. recently shared how adopting automation has transformed their operations. It has helped them produce faster, maintain higher quality, and remain flexible in changing markets. With robots becoming more user friendly and adaptable, they have been able to shift a significant portion of their workload to automation by reallocating and upskilling their team rather. This approach has positioned them for ongoing growth and success.

Their experience shows that investing in automation can deliver quick results and generate a strong return on investment. It is not just a look to the future. It is a smart move you can make today. As technology continues to advance, there is always more to learn. With the right support, you can confidently take the next step. Embracing automation now is not just about staying competitive. It is about building a more resilient and innovative manufacturing future rooted in partnership, progress, and shared success.

Read More

CNC Machine Products Inc. recently shared how adopting automation has transformed their operations. It has helped them produce faster, maintain higher quality, and remain flexible in changing markets. With robots becoming more user friendly and adaptable, they have been able to shift a significant portion of their workload to automation by reallocating and upskilling their team rather. This approach has positioned them for ongoing growth and success.

Their experience shows that investing in automation can deliver quick results and generate a strong return on investment. It is not just a look to the future. It is a smart move you can make today. As technology continues to advance, there is always more to learn. With the right support, you can confidently take the next step. Embracing automation now is not just about staying competitive. It is about building a more resilient and innovative manufacturing future rooted in partnership, progress, and shared success.

CNC Machine Products Inc. recently shared how adopting automation has transformed their operations. It has helped them produce faster, maintain higher quality, and remain flexible in changing markets. With robots becoming more user friendly and adaptable, they have been able to shift a significant portion of their workload to automation by reallocating and upskilling their team rather. This approach has positioned them for ongoing growth and success.

Their experience shows that investing in automation can deliver quick results and generate a strong return on investment. It is not just a look to the future. It is a smart move you can make today. As technology continues to advance, there is always more to learn. With the right support, you can confidently take the next step. Embracing automation now is not just about staying competitive. It is about building a more resilient and innovative manufacturing future rooted in partnership, progress, and shared success.

Crafting the Future: Internships and Mentorship in Robotics

Discover how internships and mentorships are essential to shaping the next generation of robotics and manufacturing professionals. This video highlights the importance of hands-on experience for students and demonstrates how companies mentoring young talent can make a significant difference. Learn why supporting and engaging with your local community helps build a stronger, smarter future for everyone.

Read More

Discover how internships and mentorships are essential to shaping the next generation of robotics and manufacturing professionals. This video highlights the importance of hands-on experience for students and demonstrates how companies mentoring young talent can make a significant difference. Learn why supporting and engaging with your local community helps build a stronger, smarter future for everyone.

Discover how internships and mentorships are essential to shaping the next generation of robotics and manufacturing professionals. This video highlights the importance of hands-on experience for students and demonstrates how companies mentoring young talent can make a significant difference. Learn why supporting and engaging with your local community helps build a stronger, smarter future for everyone.

Precision and Protection: Robotic Systems for Press Brake Safety

Discover how automation is transforming manufacturing at Great Dane, North America's leading trailer producer. An operator shares how robotic systems keep work engaging and help handle heavy parts—each weighing up to 120 pounds—with less physical strain. Automating tasks like lifting has improved ergonomics, eliminated back pain, and enhanced safety standards.

With faster, more accurate part formation and nonstop consistency, automation has sped up production and strengthened workforce retention by reducing manual, physically demanding work. This transformation highlights the significant benefits of embracing advanced robotics for safety, efficiency, and quality.

If you are looking to improve productivity, worker safety, and operational consistency—while supporting your team—exploring smart automation solutions can be a game-changer. Reach out or visit acieta.com to learn how tailored automation can help you achieve your production goals.

Read More

Discover how automation is transforming manufacturing at Great Dane, North America's leading trailer producer. An operator shares how robotic systems keep work engaging and help handle heavy parts—each weighing up to 120 pounds—with less physical strain. Automating tasks like lifting has improved ergonomics, eliminated back pain, and enhanced safety standards.

With faster, more accurate part formation and nonstop consistency, automation has sped up production and strengthened workforce retention by reducing manual, physically demanding work. This transformation highlights the significant benefits of embracing advanced robotics for safety, efficiency, and quality.

If you are looking to improve productivity, worker safety, and operational consistency—while supporting your team—exploring smart automation solutions can be a game-changer. Reach out or visit acieta.com to learn how tailored automation can help you achieve your production goals.

Discover how automation is transforming manufacturing at Great Dane, North America's leading trailer producer. An operator shares how robotic systems keep work engaging and help handle heavy parts—each weighing up to 120 pounds—with less physical strain. Automating tasks like lifting has improved ergonomics, eliminated back pain, and enhanced safety standards.

With faster, more accurate part formation and nonstop consistency, automation has sped up production and strengthened workforce retention by reducing manual, physically demanding work. This transformation highlights the significant benefits of embracing advanced robotics for safety, efficiency, and quality.

If you are looking to improve productivity, worker safety, and operational consistency—while supporting your team—exploring smart automation solutions can be a game-changer. Reach out or visit acieta.com to learn how tailored automation can help you achieve your production goals.

Elevate Efficiency: Advancing Press Brake Automation

See how Great Dane, North America's premier trailer manufacturer with over 120 years of experience, has transformed their manufacturing operations by integrating advanced press brake automation. Their approach has improved precision, increased productivity, and enhanced worker safety and ergonomics—allowing them to streamline operations and maintain a competitive edge.

If your organization is seeking ways to optimize efficiency, reduce downtime, and elevate safety standards, our expertise in automation solutions can support your journey. We work with you to identify the best opportunities to automate repetitive tasks, improve workflows, and empower your skilled team to adapt quickly to changing demands. Together, we can help your facility reach new levels of performance and safety.

Read More

See how Great Dane, North America's premier trailer manufacturer with over 120 years of experience, has transformed their manufacturing operations by integrating advanced press brake automation. Their approach has improved precision, increased productivity, and enhanced worker safety and ergonomics—allowing them to streamline operations and maintain a competitive edge.

If your organization is seeking ways to optimize efficiency, reduce downtime, and elevate safety standards, our expertise in automation solutions can support your journey. We work with you to identify the best opportunities to automate repetitive tasks, improve workflows, and empower your skilled team to adapt quickly to changing demands. Together, we can help your facility reach new levels of performance and safety.

See how Great Dane, North America's premier trailer manufacturer with over 120 years of experience, has transformed their manufacturing operations by integrating advanced press brake automation. Their approach has improved precision, increased productivity, and enhanced worker safety and ergonomics—allowing them to streamline operations and maintain a competitive edge.

If your organization is seeking ways to optimize efficiency, reduce downtime, and elevate safety standards, our expertise in automation solutions can support your journey. We work with you to identify the best opportunities to automate repetitive tasks, improve workflows, and empower your skilled team to adapt quickly to changing demands. Together, we can help your facility reach new levels of performance and safety.

Optimizing Food and Beverage Operations with a Dual-Function Robotic Palletizer

In this video, we showcase a custom robotic palletizing solution designed specifically for a food and beverage manufacturer. This customer sought to enhance their palletizing operations following upstream changes, aiming for a single, efficient system capable of handling both bulk glass bottles and cases simultaneously on the same production line.

Our engineering team delivered an adaptable, all-in-one solution featuring:

- A 1-to-4 leaning system that efficiently splits single-file bottles into multiple lines for streamlined processing

- A dedicated robotic sweep system that assembles full pallets of bulk glass bottles

- Integrated functionality for both bottle and case palletizing, ensuring versatility and efficiency

This upgrade not only improved throughput for our customer but also reduced manual handling and optimized floor space, contributing to a more efficient operation in the food and beverage sector.

Read More

In this video, we showcase a custom robotic palletizing solution designed specifically for a food and beverage manufacturer. This customer sought to enhance their palletizing operations following upstream changes, aiming for a single, efficient system capable of handling both bulk glass bottles and cases simultaneously on the same production line.

Our engineering team delivered an adaptable, all-in-one solution featuring:

- A 1-to-4 leaning system that efficiently splits single-file bottles into multiple lines for streamlined processing

- A dedicated robotic sweep system that assembles full pallets of bulk glass bottles

- Integrated functionality for both bottle and case palletizing, ensuring versatility and efficiency

This upgrade not only improved throughput for our customer but also reduced manual handling and optimized floor space, contributing to a more efficient operation in the food and beverage sector.

In this video, we showcase a custom robotic palletizing solution designed specifically for a food and beverage manufacturer. This customer sought to enhance their palletizing operations following upstream changes, aiming for a single, efficient system capable of handling both bulk glass bottles and cases simultaneously on the same production line.

Our engineering team delivered an adaptable, all-in-one solution featuring:

- A 1-to-4 leaning system that efficiently splits single-file bottles into multiple lines for streamlined processing

- A dedicated robotic sweep system that assembles full pallets of bulk glass bottles

- Integrated functionality for both bottle and case palletizing, ensuring versatility and efficiency

This upgrade not only improved throughput for our customer but also reduced manual handling and optimized floor space, contributing to a more efficient operation in the food and beverage sector.

Troubleshooting FANUC SRVO-007 External Emergency Stop Alarm

In this video, our FANUC Master Certified service expert walks you through the process of diagnosing and resolving the SRVO-007 External Emergency Stop Alarm. This alarm typically occurs when there’s an issue with the external emergency stop circuit, preventing the robot from operating normally. Learn how to identify common causes, perform step-by-step troubleshooting, and ensure safe and effective resolution. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

In this video, our FANUC Master Certified service expert walks you through the process of diagnosing and resolving the SRVO-007 External Emergency Stop Alarm. This alarm typically occurs when there’s an issue with the external emergency stop circuit, preventing the robot from operating normally. Learn how to identify common causes, perform step-by-step troubleshooting, and ensure safe and effective resolution. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

In this video, our FANUC Master Certified service expert walks you through the process of diagnosing and resolving the SRVO-007 External Emergency Stop Alarm. This alarm typically occurs when there’s an issue with the external emergency stop circuit, preventing the robot from operating normally. Learn how to identify common causes, perform step-by-step troubleshooting, and ensure safe and effective resolution. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Troubleshooting FANUC SRVO-050 Collision Detect Alarm

In this video, our FANUC Master Certified service expert provides a brief guide to troubleshooting the SRVO-050 Collision Detect Alarm, a common issue in robotic systems. Learn how to identify the causes behind this alarm, step-by-step procedures for resolving it, and tips for preventing future occurrences. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

In this video, our FANUC Master Certified service expert provides a brief guide to troubleshooting the SRVO-050 Collision Detect Alarm, a common issue in robotic systems. Learn how to identify the causes behind this alarm, step-by-step procedures for resolving it, and tips for preventing future occurrences. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

In this video, our FANUC Master Certified service expert provides a brief guide to troubleshooting the SRVO-050 Collision Detect Alarm, a common issue in robotic systems. Learn how to identify the causes behind this alarm, step-by-step procedures for resolving it, and tips for preventing future occurrences. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Troubleshooting FANUC SRVO-062 and SRVO-065 Battery Alarms

In this video, our FANUC Master Certified service expert walks you through troubleshooting the SRVO-062 and SRVO-065 battery alarms—two of the most frequent issues that can disrupt your robot’s performance. Learn how to diagnose the problem, understand the underlying causes, and implement the right solutions to restore your system quickly. This guide is meant to help you manage these battery-related alarms and ensure your FANUC robot stays in top working condition. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

In this video, our FANUC Master Certified service expert walks you through troubleshooting the SRVO-062 and SRVO-065 battery alarms—two of the most frequent issues that can disrupt your robot’s performance. Learn how to diagnose the problem, understand the underlying causes, and implement the right solutions to restore your system quickly. This guide is meant to help you manage these battery-related alarms and ensure your FANUC robot stays in top working condition. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

In this video, our FANUC Master Certified service expert walks you through troubleshooting the SRVO-062 and SRVO-065 battery alarms—two of the most frequent issues that can disrupt your robot’s performance. Learn how to diagnose the problem, understand the underlying causes, and implement the right solutions to restore your system quickly. This guide is meant to help you manage these battery-related alarms and ensure your FANUC robot stays in top working condition. Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Troubleshooting FANUC SRVO-402 DCS Alarm

In this video, our FANUC Master Certified service expert takes you step-by-step through diagnosing and resolving the SRVO-402 DCS Alarm, one of the most common issues that can arise in robotic systems. Whether you're a technician, integrator, or maintenance engineer, this detailed walk-through will help you understand the root causes and effective solutions to get your system back in operation.

Watch now to learn the best practices for troubleshooting, tips for avoiding common pitfalls, and insights into optimizing your FANUC robot's performance! Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

In this video, our FANUC Master Certified service expert takes you step-by-step through diagnosing and resolving the SRVO-402 DCS Alarm, one of the most common issues that can arise in robotic systems. Whether you're a technician, integrator, or maintenance engineer, this detailed walk-through will help you understand the root causes and effective solutions to get your system back in operation.

Watch now to learn the best practices for troubleshooting, tips for avoiding common pitfalls, and insights into optimizing your FANUC robot's performance! Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

In this video, our FANUC Master Certified service expert takes you step-by-step through diagnosing and resolving the SRVO-402 DCS Alarm, one of the most common issues that can arise in robotic systems. Whether you're a technician, integrator, or maintenance engineer, this detailed walk-through will help you understand the root causes and effective solutions to get your system back in operation.

Watch now to learn the best practices for troubleshooting, tips for avoiding common pitfalls, and insights into optimizing your FANUC robot's performance! Please note, all troubleshooting should be performed by qualified personnel, and Acieta is not liable for any damages resulting from improper maintenance or failure to follow safety procedures.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: