Increase throughput and reduce costs to stay competitive with Acieta's FastARC PW port welder robotic solution.

Videos

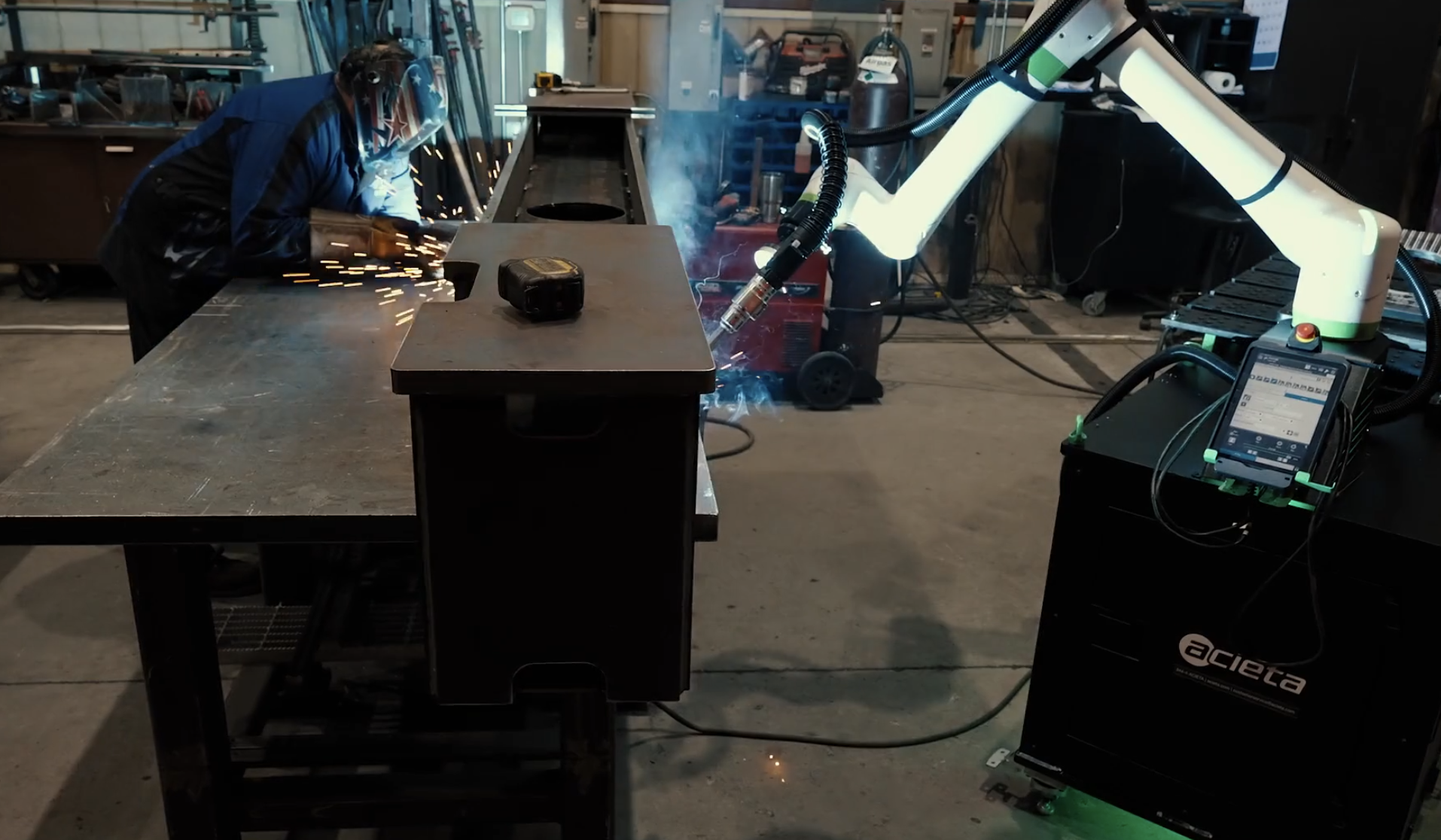

Port welding robotic solution takes hydraulic cylinder fabrication to a new level

Welding is an essential but often dangerous and physically demanding job. Prince Hydraulics worked with Acieta to make the repetitive tasks easier and more enjoyable with the Port Welder. Find out why the Port Welder is the future of welding in hydraulics and why it's worth considering for your operations. Get ready to be amazed by the power of robotics in action! Visit acieta.com for more information.

Read More

Welding is an essential but often dangerous and physically demanding job. Prince Hydraulics worked with Acieta to make the repetitive tasks easier and more enjoyable with the Port Welder. Find out why the Port Welder is the future of welding in hydraulics and why it's worth considering for your operations. Get ready to be amazed by the power of robotics in action! Visit acieta.com for more information.

Welding is an essential but often dangerous and physically demanding job. Prince Hydraulics worked with Acieta to make the repetitive tasks easier and more enjoyable with the Port Welder. Find out why the Port Welder is the future of welding in hydraulics and why it's worth considering for your operations. Get ready to be amazed by the power of robotics in action! Visit acieta.com for more information.

FastARC® CW welding robot for low volume/high mix shops

For the low volume/high mix shop, Acieta’s new FastARC CW welding robot offers simple programming for quick changeovers and same-day setup. The FastARC CW is typically ready to deliver in just a few weeks, so shops can be up and running in no time. Visit acieta.com/cw for more information.

Read More

For the low volume/high mix shop, Acieta’s new FastARC CW welding robot offers simple programming for quick changeovers and same-day setup. The FastARC CW is typically ready to deliver in just a few weeks, so shops can be up and running in no time. Visit acieta.com/cw for more information.

For the low volume/high mix shop, Acieta’s new FastARC CW welding robot offers simple programming for quick changeovers and same-day setup. The FastARC CW is typically ready to deliver in just a few weeks, so shops can be up and running in no time. Visit acieta.com/cw for more information.

Robots: exciting careers for today and the future

The career opportunities in robotics are limitless—from programmer and engineer to service technician and electrical assembler, to name a few. If you like gaming and computers, solving challenges creatively, and/or working with your hands on mechanical systems, robotics may be a great career path for you. Hear more from Acieta teammates who love working with robots.

Read More

The career opportunities in robotics are limitless—from programmer and engineer to service technician and electrical assembler, to name a few. If you like gaming and computers, solving challenges creatively, and/or working with your hands on mechanical systems, robotics may be a great career path for you. Hear more from Acieta teammates who love working with robots.

The career opportunities in robotics are limitless—from programmer and engineer to service technician and electrical assembler, to name a few. If you like gaming and computers, solving challenges creatively, and/or working with your hands on mechanical systems, robotics may be a great career path for you. Hear more from Acieta teammates who love working with robots.

Acieta accelerate growth by integrating robotic automation

Tony takes a tour at Acieta. Nearly all modern manufacturers have an opportunity to accelerate growth by integrating robotic automation into their facility. With decades of experience integrating industry-leading equipment, we are the right partner to empower customers for the next generation of manufacturing.

Read More

Tony takes a tour at Acieta. Nearly all modern manufacturers have an opportunity to accelerate growth by integrating robotic automation into their facility. With decades of experience integrating industry-leading equipment, we are the right partner to empower customers for the next generation of manufacturing.

Tony takes a tour at Acieta. Nearly all modern manufacturers have an opportunity to accelerate growth by integrating robotic automation into their facility. With decades of experience integrating industry-leading equipment, we are the right partner to empower customers for the next generation of manufacturing.

Robotic Welding with Tony Gunn and MTDCNC

Automated welding has been around for decades and understandably provides its user with gains in production and reliability. Tony visits Acieta to talk about the solutions they offer to industry and how technologies in welding continually advance helping manufacturers in all industries.

Read More

Automated welding has been around for decades and understandably provides its user with gains in production and reliability. Tony visits Acieta to talk about the solutions they offer to industry and how technologies in welding continually advance helping manufacturers in all industries.

Automated welding has been around for decades and understandably provides its user with gains in production and reliability. Tony visits Acieta to talk about the solutions they offer to industry and how technologies in welding continually advance helping manufacturers in all industries.

This FANUC COBOT is as easy to use as App’s on my phone

If you're in search of one of the easiest and most reliable methods of automation then consider this from FANUC. Tony is at Steakfest in North America where one of the solutions he's interrogating is the new CRX ROBOT from FANUC available and supported in North America by Acieta. Just #soeasy

Read More

If you're in search of one of the easiest and most reliable methods of automation then consider this from FANUC. Tony is at Steakfest in North America where one of the solutions he's interrogating is the new CRX ROBOT from FANUC available and supported in North America by Acieta. Just #soeasy

If you're in search of one of the easiest and most reliable methods of automation then consider this from FANUC. Tony is at Steakfest in North America where one of the solutions he's interrogating is the new CRX ROBOT from FANUC available and supported in North America by Acieta. Just #soeasy

New ways to load and unload machine tools

Tony visits Acieta in North America to learn more about modern and flexible ways of loading and unloading machine tools. We watch COBOTS in action and see why many machine shops are opting for these safe, flexible automation solutions.

Read More

Tony visits Acieta in North America to learn more about modern and flexible ways of loading and unloading machine tools. We watch COBOTS in action and see why many machine shops are opting for these safe, flexible automation solutions.

Tony visits Acieta in North America to learn more about modern and flexible ways of loading and unloading machine tools. We watch COBOTS in action and see why many machine shops are opting for these safe, flexible automation solutions.

Acieta – if it’s down, we fix it 24 hours a day

Automation is only good if it's running efficiently. In this video, learn about our service and support, customer service and support 24 hours a day, 7 days week!

Read More

Automation is only good if it's running efficiently. In this video, learn about our service and support, customer service and support 24 hours a day, 7 days week!

Automation is only good if it's running efficiently. In this video, learn about our service and support, customer service and support 24 hours a day, 7 days week!

Fabricator Streamlines Entire Operation with the Addition of a New Welding Robot from Acieta

Fabricator MDS has streamlined its operations, improved part quality, increased output, and more accurately predicts lead times thanks to a FastARC® 2HT welding solution from Acieta. Now employees can focus on more challenging work and leave the repetitive sub-assembly welds to the robot. “The FastARC 2HT has over-exceeded our expectations.” Visit acieta.com for more information.

Read More

Fabricator MDS has streamlined its operations, improved part quality, increased output, and more accurately predicts lead times thanks to a FastARC® 2HT welding solution from Acieta. Now employees can focus on more challenging work and leave the repetitive sub-assembly welds to the robot. “The FastARC 2HT has over-exceeded our expectations.” Visit acieta.com for more information.

Fabricator MDS has streamlined its operations, improved part quality, increased output, and more accurately predicts lead times thanks to a FastARC® 2HT welding solution from Acieta. Now employees can focus on more challenging work and leave the repetitive sub-assembly welds to the robot. “The FastARC 2HT has over-exceeded our expectations.” Visit acieta.com for more information.

Preventive Maintenance for a FANUC R-2000iC 165F Robot

Learn how to perform preventive maintenance on a FANUC R-2000iC 165F floor-mounted robot. Chris Bosquez, Robotic Systems Engineer at Acieta, walks through the steps to add grease and change batteries.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

Learn how to perform preventive maintenance on a FANUC R-2000iC 165F floor-mounted robot. Chris Bosquez, Robotic Systems Engineer at Acieta, walks through the steps to add grease and change batteries.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Learn how to perform preventive maintenance on a FANUC R-2000iC 165F floor-mounted robot. Chris Bosquez, Robotic Systems Engineer at Acieta, walks through the steps to add grease and change batteries.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Preventive Maintenance for a FANUC M-10iA, M-20iA Robot

Chris Bosquez, Robotic Systems Engineer at Acieta, explains the proper steps to add grease and oil, and change batteries on a FANUC M-10iA, M-20iA robot.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Read More

Chris Bosquez, Robotic Systems Engineer at Acieta, explains the proper steps to add grease and oil, and change batteries on a FANUC M-10iA, M-20iA robot.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

Chris Bosquez, Robotic Systems Engineer at Acieta, explains the proper steps to add grease and oil, and change batteries on a FANUC M-10iA, M-20iA robot.

Disclaimer:

This video is provided solely for informational and visual reference purposes only. It is not intended to serve as a comprehensive training guide or to replace proper formal training and certification. Performing robot maintenance without appropriate training and qualifications can result in serious injury, equipment damage, and voiding manufacturer warranties.

By viewing this video, you acknowledge that maintenance actions should only be performed by trained and qualified personnel. For safe and reliable service, please schedule official training or contact our Service Department at 844-4-ACIETA to arrange professional support. The company assumes no liability for damages, injuries, or operational failures resulting from unqualified maintenance efforts or improper procedures.

Always follow manufacturer guidelines and safety protocols.

To discuss known AUTOMATION OPPORTUNITIES or discover new ones: