Tired of the struggles to produce high-quality products on time and on budget? Short on skilled welders? Want to lower your price to be globally competitive?

It’s time to shake up your production with the FastARC PW robotic port welder. Designed in collaboration with a cylinder manufacturer, the FastARC PW is purpose-built for the unique challenges of welding ports on hydraulic cylinders.

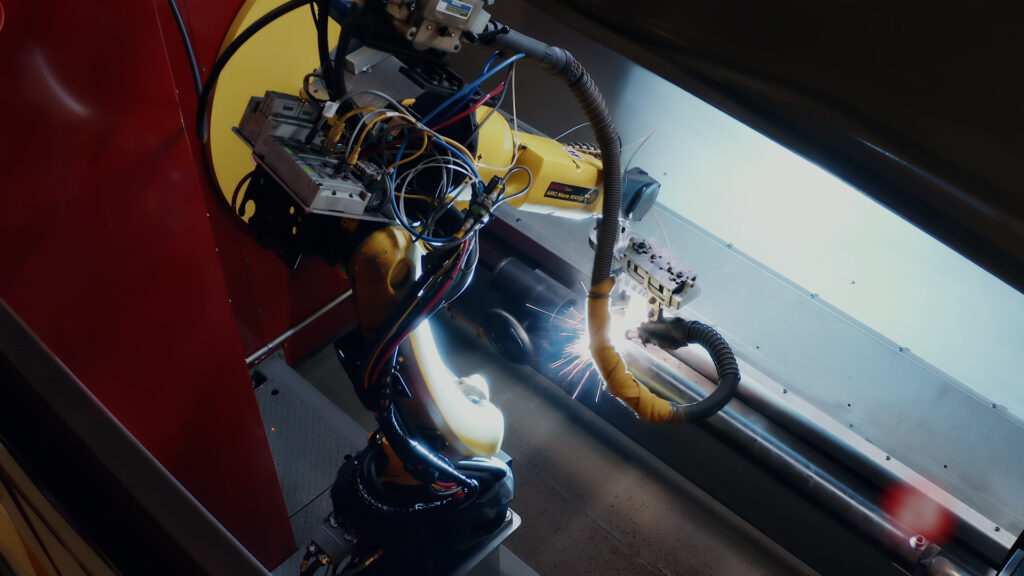

The system features a FANUC 6-axis robot, designed for purpose end of arm tooling, and a Ferris wheel positioner for part presentation and load/unload during machine time. FastARC PW is compatible with Miller®, Lincoln® Electric and Fronius welding equipment.