Boosting Productivity Through Efficiency and Precision

A primary goal for any manufacturing operation is to increase productivity, and robotic automation is a key driver in achieving this objective. Robots are designed to operate at a consistently high level of efficiency and precision, significantly enhancing production rates and product quality. Robot consistency ensures that production targets are met and often exceeded, with a marked reduction in errors and defects.

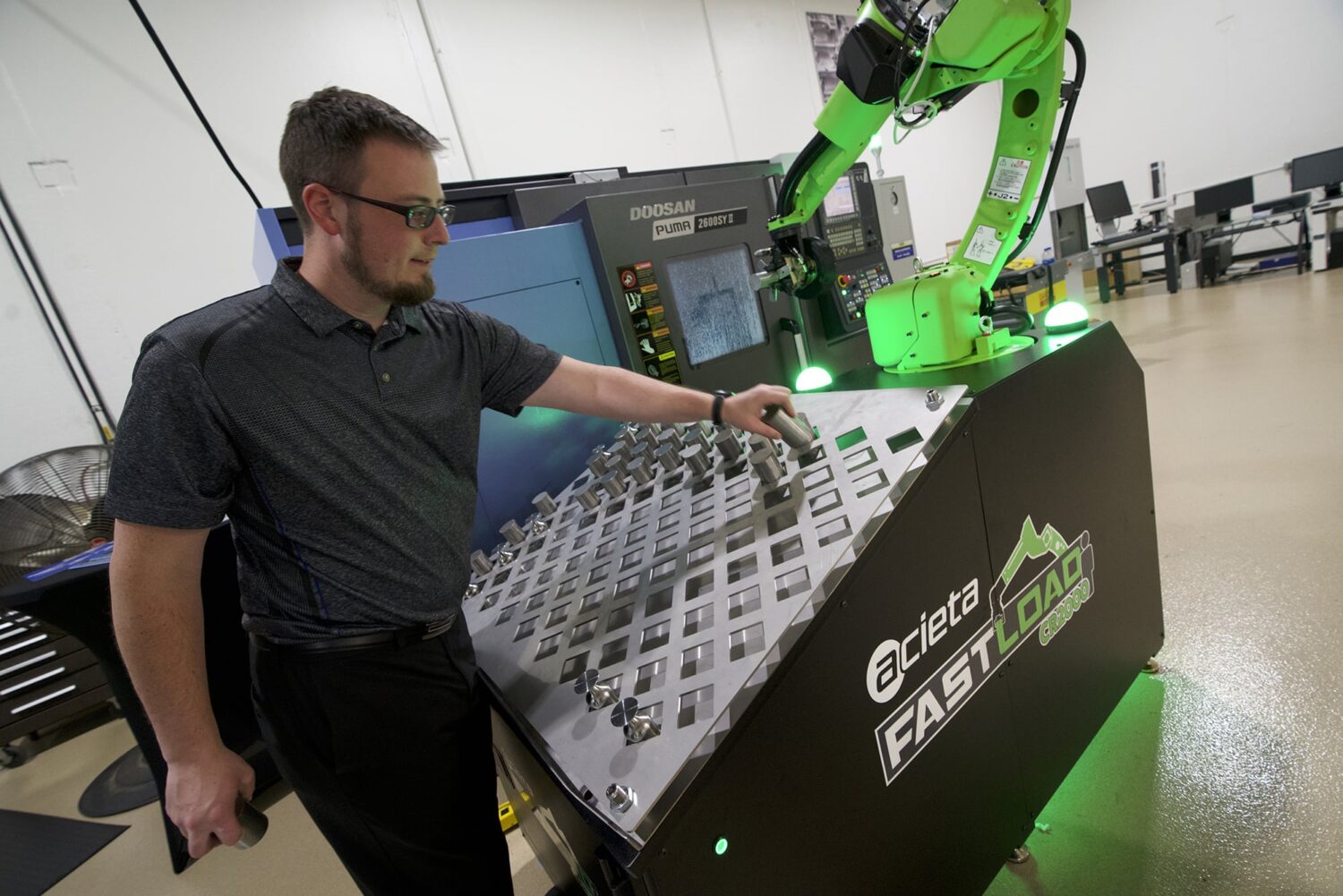

Robots can be deployed for repetitive and high-volume tasks, freeing up human workers to focus on more complex and strategic activities that add greater value to the manufacturing process. This not only improves overall productivity but also optimizes the use of employees’ skills and creativity in the workplace. By integrating robotic automation, manufacturers can achieve a more streamlined, efficient, and productive operation, effectively boosting their output and competitiveness in the market.