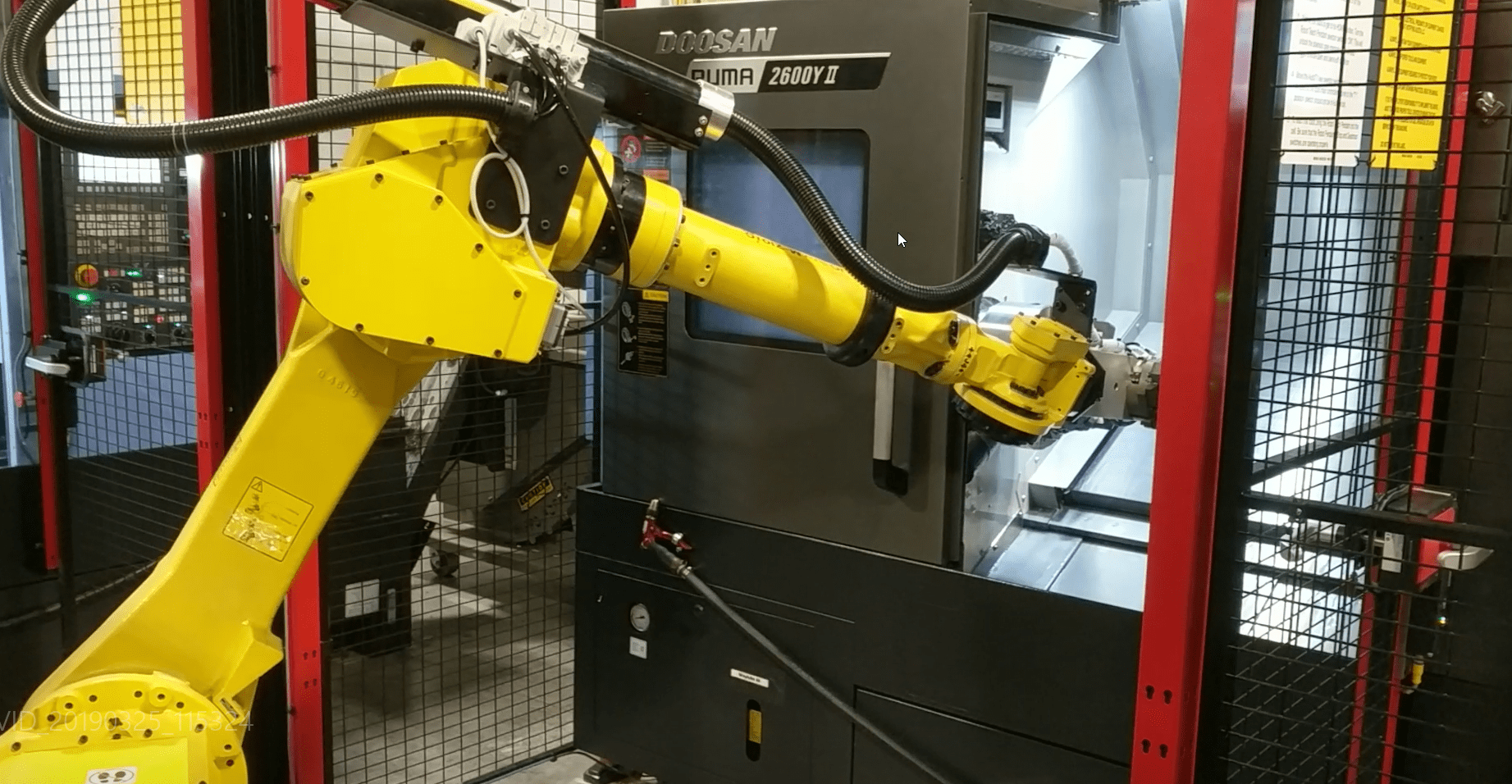

Material Handling Robots In Action

Robotic material handling equipment cuts costs because it does the kind of arduous work humans aren’t suited for. They’ll lift massive payloads — the largest FANUC robot can tote more than 2,866 pounds (1300kg) at one time — and place them to within a few thousandths of an inch all day and all night.

Lifting is a leading cause of workplace injuries, and it costs employers millions each year. Automating material handling tasks with robotic material handling systems, such as bin-picking robots, creates a better environment for workers and protects employers against compensation claims.

When thinking about robotic material handling systems, the primary considerations should be payload and reach. Together they dictate the size of robot needed, although it’s often worth over-specifying because robots are easily reassigned to new tasks as the mix of orders through a shop ebbs and flows. The more material handling robot applications your system can handle, the more effective it will be.