Blog

Join us at the 2021 Wichita Industrial Trade Show

We invite you to visit with us at the 2021 Wichita Industrial Trade Show in Wichita, Kansas, Oct. 26 to 28. We will be running two collaborative robot demos in our booth, as well as presenting important information about how robot cells can address key business challenges and boost ROI in no time. ROBOT DEMOS ... Join us at the 2021 Wichita Industrial Trade Show

Collaborative Robot Solution Featured at WESTEC 2021

Join us at WESTEC 2021, Nov. 16 – 18 in Long Beach, Calif. In booth #2122 as well as join our discussion addressing labor shortages and increasing future growth! ROBOT DEMO Stop by Acieta booth 2122 to see the new collaborative FastLOAD CX1000 expandable robotic solution in action. See why it’s been called the easiest ... Collaborative Robot Solution Featured at WESTEC 2021

Let’s talk about robots at FABTECH 2021

Acieta is bringing its deep technical knowledge and industry experience in robotics to FABTECH 2021, and we invite you to join us. Labor shortages, shorter lead times, and international competition are putting overwhelming pressures on manufacturers. Robotics may be your solution to these problems. We help manufacturers do more with less. At FABTECH 2021, Acieta ... Let’s talk about robots at FABTECH 2021

Prepare for the Unexpected with Automation

Around the world, in the wake of the COVID-19 pandemic, manufacturers have had to completely pivot normal production to accommodate higher demands, a dwindling workforce, and more regulations on how to safely move forward. Though no manufacturer looks the same, those who have started their journey into robotic automation are experiencing an often unspoken benefit ... Prepare for the Unexpected with Automation

The Top 7 Autonomous Mobile Cobot FAQs

As the next step in industrial automation, the use of autonomous mobile cobots is increasingly on the rise in facilities looking to maximize productivity, introduce or expand automation, and pursue innovative robotic opportunities. Below, we will answer some common questions about mobile cobots, sharing information about what they are and what they can do. Frequently ... The Top 7 Autonomous Mobile Cobot FAQs

How Do Automation Robots Benefit Society?

Over the past century, automation has made an immeasurable impact on manufacturing, and it continues to do so to this day. From vast improvements in worker safety to facilitating the 40-hour workweek, manufacturing and industry as we now know them would not be possible without automation. You may have heard conversations or read articles positing ... How Do Automation Robots Benefit Society?

The Effects Of Automation On The Economy

Automation has been part of the industrial landscape for decades and continues to expand as new technology is developed. Designed to fulfill some of the most repetitive and/or dangerous tasks, automation can provide numerous advantages to organizations, employees and the economy, which accounts for its continued growth throughout the manufacturing sector. A few benefits of ... The Effects Of Automation On The Economy

Automation Solving Unpredictable Downtime

Robotic automation solutions not only help save floor space, increase productivity, and improve plant efficiency, they are also fundamental in creating peace of mind during uncertain times. Whether it’s a health pandemic, economic recession, political shifts or labor shortages, robotic automation ensures production can continue, regardless of limitations or regulations. Leaders can shift focus to ... Automation Solving Unpredictable Downtime

Thinking of Joining the Acieta Team? This is Why You’ll Love it Here.

As the world begins to embrace automation and robotics, there has been a rise in demand for automation specialists. To accommodate growing demand, Acieta has updated our facility and is looking for people who want to help us shape the future of automation. Automation is an industry poised for growth and with that growth comes ... Thinking of Joining the Acieta Team? This is Why You’ll Love it Here.

What Is Automated Welding?

Manual welding requires an operator to maintain consistent torch orientation and arc length over a long production run. Fatigue leads to mistakes and lower output. Automation solves these problems. Most forms of welding can be automated. Arc welding, resistance/ spot welding, and less common variants such as ultrasonic welding or submerged arc are all good ... What Is Automated Welding?

Benefits Of Automated Welding

Welding is an essential manufacturing process, and it’s also one of the hardest to master. Metal arc welding is especially difficult because it requires maintaining a consistent torch orientation and arc length. FastArc Weld Cells provide these consistencies, resulting in four areas of benefits: Improved quality Increased capacity Lower costs Safer working conditions Improved quality: ... Benefits Of Automated Welding

10 Trends Affecting Industrial Automation

Robotic Automation improves quality and cuts costs, but the real reason manufacturers automate is ROI. Realizing the projected savings hinges on minimizing implementation costs while maximizing equipment utilization. Both are getting easier, thanks to these 10 industrial automation trends. 1. Industrial Internet of Things (IIoT) Technology As demand grows, sensors for data acquisition are becoming ... 10 Trends Affecting Industrial Automation

Fabtech 2017: Booth A4014

See the Key to Better Productivity: State-of-the-Art robotic bending system in action at Fabtech Booth A4014 Labor shortages are a problem more than ever before, and it’s costing everyone valuable time and money. It’s incredibly difficult to hire workers for repetitive, dirty, dangerous and boring jobs, and it’s nearly impossible to retain workers in those ... Fabtech 2017: Booth A4014

Why Being Innovative With Automation Should Be A Priority For Your Company

Why Automation Should Be A Priority For Your Company Manufacturers in every industry are investing in robotic automation. Companies in food and consumer goods, electronics, metal processing and the automotive sector are using robots to improve productivity and reduce costs. However, just automating existing processes may not be enough to stay competitive in international markets. ... Why Being Innovative With Automation Should Be A Priority For Your Company

Plant Automation’s Promising Future: Empowered Management, Simplified Tasks

Robotic manufacturing solutions are changing the way factories operate in every industry. Efficiencies are improving and production is becoming more stable and consistent. Capacity and productivity are on the rise while employees are better protected from dirty, dangerous activities. Underway in large, medium, and small businesses alike, these changes impact practically every aspect of manufacturing. ... Plant Automation’s Promising Future: Empowered Management, Simplified Tasks

Manufacturing With Robots Helps Data Collection

If you can measure it, you can improve upon it. That’s why industries from aerospace and automotive to foundries and pharmaceuticals capture all the process data they can. For generations, those numbers were logged manually, and production workers themselves were a valuable source of information. Yet with repetitive, dirty and dangerous operations increasingly performed by ... Manufacturing With Robots Helps Data Collection

Facts About Robots That Everyone Should Know

Few machines evoke as much concern and outright fear as the industrial robot. Perhaps the problem is those journalists and “experts” who sound like modern day Paul Reveres crying, “The robots are coming! The robots are coming!” Of course, they’re not wrong. Industrial robots are on the rise, but that doesn’t mean they’re rising up. ... Facts About Robots That Everyone Should Know

How Manufacturing Robotics Are Creating Jobs

It’s common knowledge that robots in manufacturing lower costs and improve quality. Businesses become more competitive and are able to grow, sometimes re-shoring manufacturing in the process. However, it is a fallacy that robots take away human jobs. Rather than cutting headcounts, companies using robots find they need more people to handle the increased volumes. ... How Manufacturing Robotics Are Creating Jobs

Integrator or OEM: Choosing the Right Robotics Partner

In recent years, we’ve been getting the question much more frequently: Is it better to work with a single-source robotic integrator or a robotics OEM when choosing a new or retrofitted robot/machine tool system? There are more robotic integrators and OEM robotic integrations available than ever before. This presents a challenge for prospective buyers who ... Integrator or OEM: Choosing the Right Robotics Partner

5 Myths about Robotic Vision Systems

5 Myths about Robotic Vision Systems Vision systems for robotic manufacturing applications have significantly evolved over the last decade. While the vision systems of old were unreliable, clunky and expensive, today’s systems are anything but. Proper vision systems can make the difference between an efficient robotic system and one that is not working optimally. Here ... 5 Myths about Robotic Vision Systems

How to Keep Your Company’s New Year’s Resolutions

Now’s that time of year when people make personal resolutions to lose weight, get organized and make more money. It’s not much different for manufacturing companies, that need to take time to review the coming year and set goals to grow business. Of top priority for most manufacturers is to streamline operations, reduce waste, improve ... How to Keep Your Company’s New Year’s Resolutions

Robotics and Job Security

The manufacturing industry faces a challenge, and it’s not coming from overseas. Quite simply, there aren’t enough skilled workers in the U.S., and the problem is going to get worse over the next 10 years. A recent report from Deloitte and the Manufacturing Institute projects 2 million unfilled jobs in manufacturing. That will crimp output ... Robotics and Job Security

The Truth About Strawberries & Robotics

Everybody likes strawberries, except, perhaps the engineer developing a robotic strawberry packing system. Like everything natural, strawberries vary greatly in size, shape and weight. Their textured surface can be wet, and they crush easily. Developing robotic gripper systems to grasp and move fruit and vegetables is challenging. Fortunately for manufacturing companies, rigid cast, molded or ... The Truth About Strawberries & Robotics

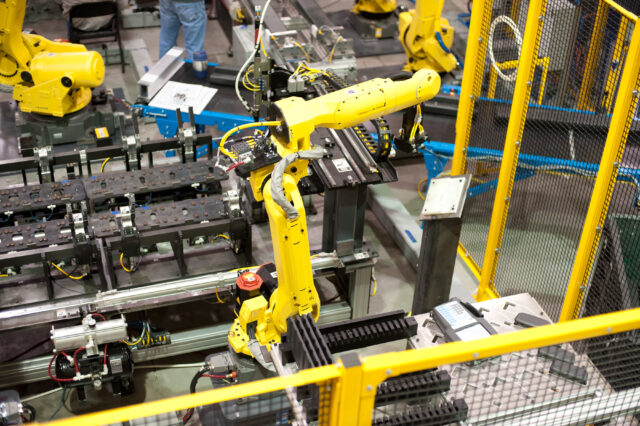

The Many Benefits Of FANUC Robotics

Robotic automation is contributing to a manufacturing renaissance. Companies are installing more robots than ever, increasing productivity and growing their businesses. Picking the right robot is no easy task. Experienced users find sticking with one brand or vendor simplifies programming, maintenance and support, providing they chose wisely. For a company making a first foray into ... The Many Benefits Of FANUC Robotics