FANUC Authorized System Integrator

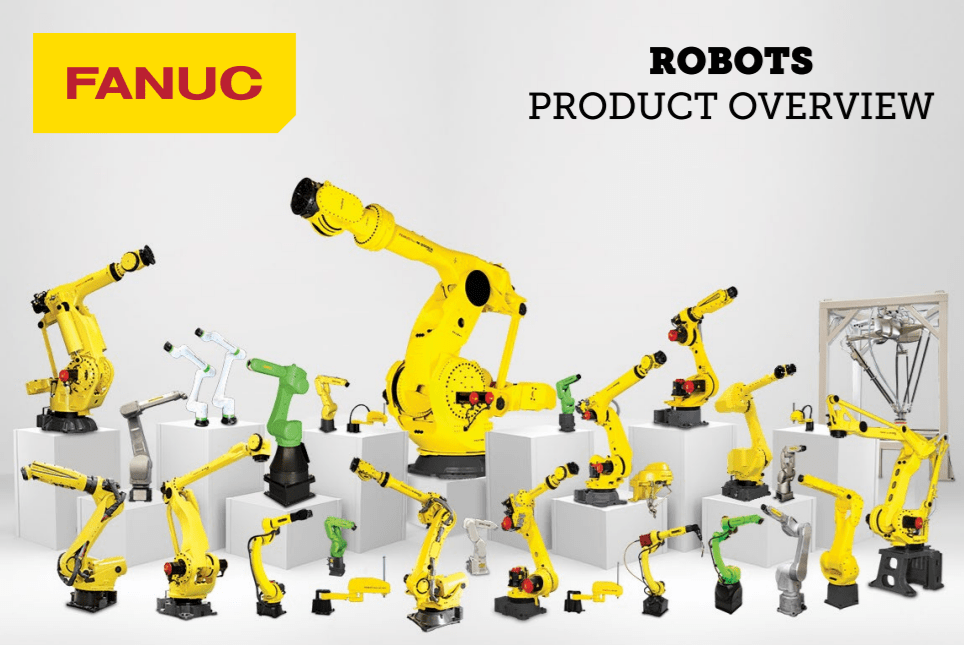

Acieta is proud to be a FANUC Authorized System Integrator, Certified Vision Specialist, and Certified Servicing Integrator, one of a very select group of robotics companies that provide excellent quality, innovation and customer satisfaction. Of all FANUC Robotics’ Authorized System Integrators, less than 2% are Certified Servicing and Vision Integrators because it requires a rigorous commitment for technicians to pass specialized testing and training. Our technicians are FANUC certified so they will always be experts on the most cutting-edge robotic solutions available.