Robotic Palletizing

Industrial palletizing robots are automated systems used to stack goods onto pallets for shipment. These can be programmed to handle a wide range of products in a variety of configurations. Because of their strength and versatility, the number of palletizing robot applications are virtually limitless.

Manufacturing companies, from fields as diverse as chemicals, food and health care, are recognizing the advantages of palletizing robots. Cases, drums, bags or trays can all be palletized quickly, accurately and repeatably, and interweaving layers as necessary. Robotic palletizing systems with payloads over 2800 lbs. can stack in whatever format is needed. Uniform ventilation gaps can be guaranteed while controlled acceleration and deceleration mean there’s no damage from dropping or banging cases together.

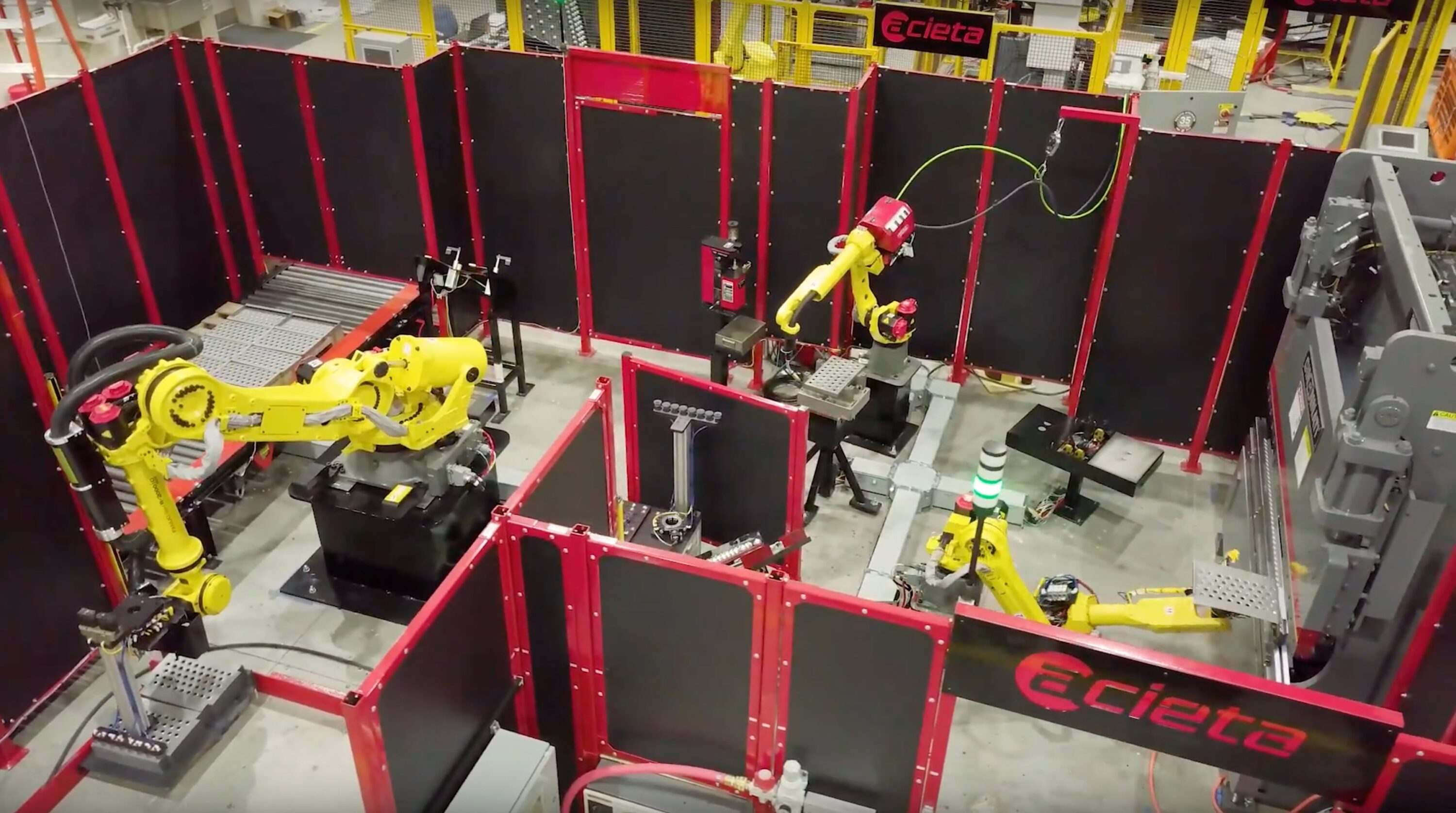

A robotic palletizing system offers many advantages, with the latest safety technology, cells take up little floor space and can go at the end of a production line. This turns a group of machines into a mini-factory and eliminates long conveyors snaking their way through to the centralized system.

When different case sizes are introduced, or bag formats changed it takes just a change of program to reconfigure the robot. Modern gripper designs mean other pack formats like large bags or trays of beverage cans are handled just as easily as rigid cartons. Some advanced systems can even handle mixed pallets, making them almost as flexible as workers.

If you’re looking for more universal palletizing robots rather than a custom palletizer, consider our FastPACK® universal palletizer. It has the capability to handle even the most complex applications, thanks to its flexible pallet arrangements and configurable inbound conveyance.