Material Removal Robots In Action

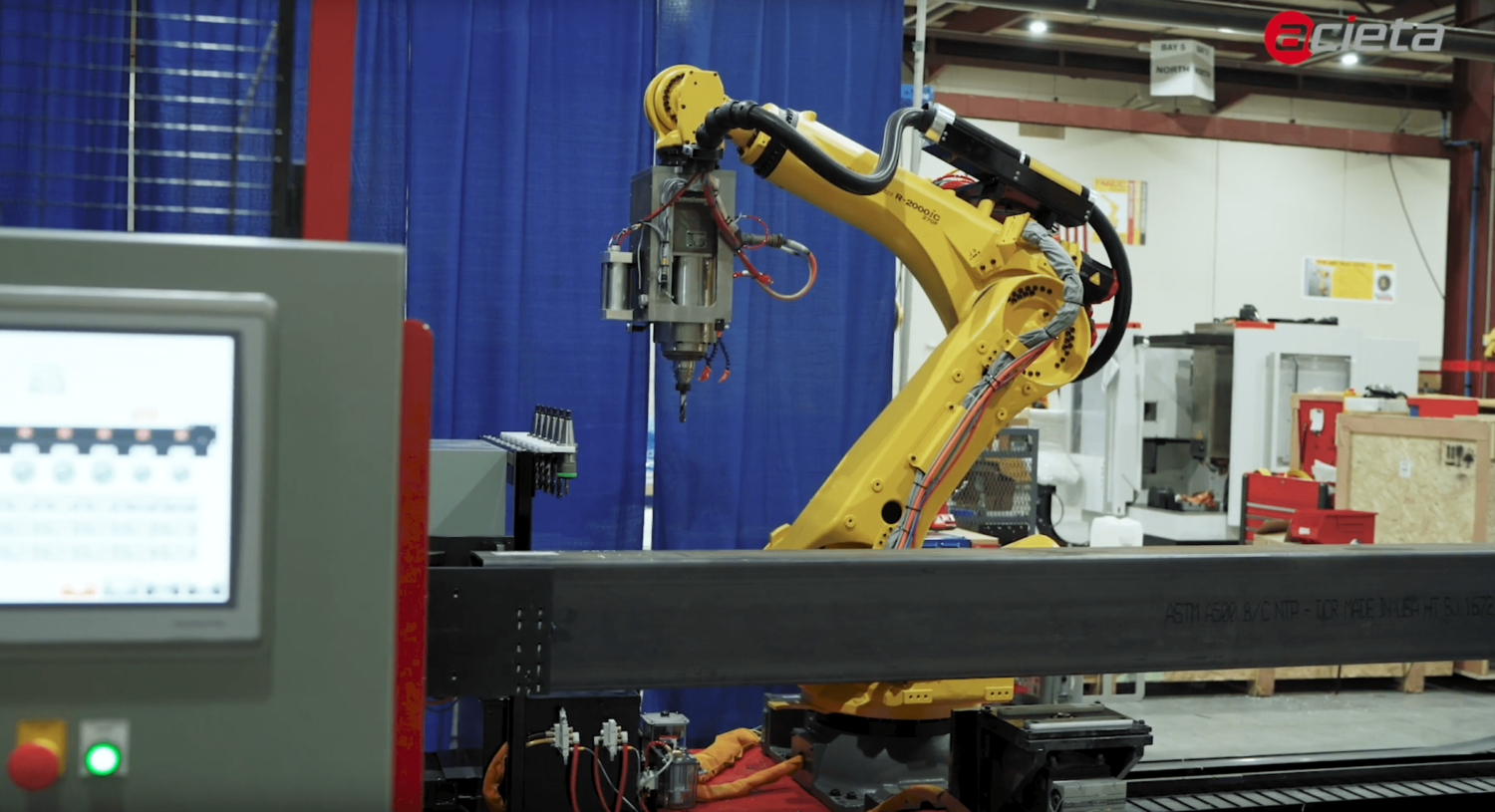

Trimming and deburring are more complex, requiring force control and often vision to handle variability in the size and position of the material to be removed. New compliant tool holders provide greater control over cutting loads and direction, creating a cleaner and more consistent edge. The robotic trimming system follows a path resulting in better consistency than the most skilled operator, meaning less variability in parts coming out of multiple dies.

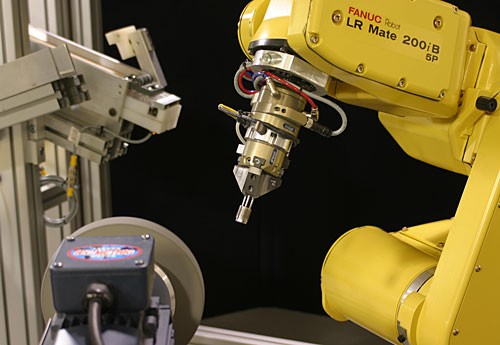

Robotic material removal doesn’t have to mean the robot holds the tool. Many applications work better when the robot holds the workpiece taking it to a fixed tool. This increases flexibility by allowing the robot to perform multiple operations.

For many manufacturers the biggest single benefit from using robotic cutting, trimming and machining is the ability to overcome a skills shortage. These jobs often have a high turnover, yet it takes time to develop the necessary skills. For companies who want to keep growing, robotic material removal is the way to go.